LIQUID

Product

A variety of mature drink formulas

The products cover a wide range of nutrition fields to meet the needs of different consumer groups.

Nutraceutical liquid or tincture.

Bottle, bag, sachet, and other specifications are available.

Manufacturing

Experience sheer & speed mixing control to tailor product nature.

Pressurized homogenising tanks capacity from 200 Litres to 1000 Litres.

In process temperature control to encourage API activities.

High pressure ultrafine membrane for product purification.

Leak check, pressure check and external sterilisation to ensure product quality.

Nitrogen sealed package to preserve product integrity.

Packaging form

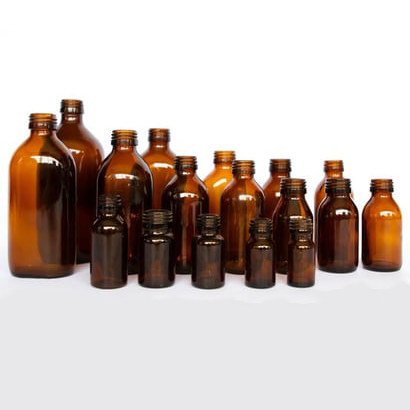

Glass bottle

400 bottle/min high-speed integrated production line.

Ultra-high temperature instantaneous sterilization (UHT) + pasteurization ensuregreater retention of nutrient activity and excellent taste, while removing the need to add food preservatives.

Safe and automated CIP online positioning cleaning system.

Filling capability range 30 - 500ml.

Portable Pouch

The modern fashion design.

Light and easy to carry.

Adapt to a variety of delivery.

Great experience for users.

We have our own bottle production line, which ensures stable quality, adopts variable frequency speed regulation and has stable performance. The transmission system is equipped with an overload automatic shutdown protection device, which is safe and reliable and reduces the pollution problem during filling and corking. It is specially used for the filling of various non-gaseous liquids, the automatic washing of bottles before filling, the pre-filling of nitrogen in bottles, and the corking after filling.

Bottle unscrambler system

The stable bottle sorting speed can meet the production of the host machine, stabilize the bottle sorting, smooth the bottle pouring, and improve the production stability.

Spray sterilization and cooling system

Satisfy production table operation, sterilization, and cooling to satisfy customer's request.

Air Knife Drying Systems

High stability provides stable and consistent air volume and air pressure to ensure that the product reaches the required dryness.