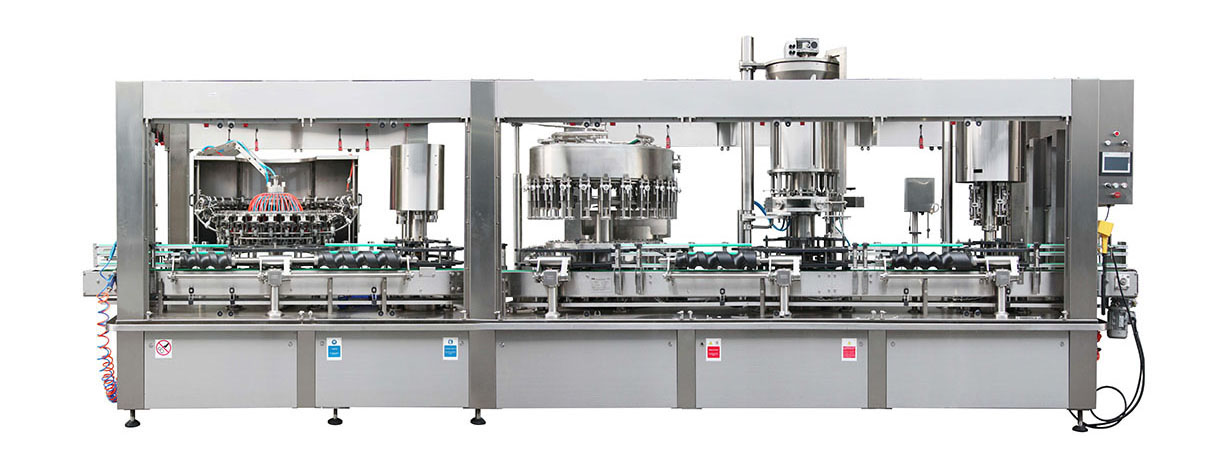

Liquid Manufacturing

Production

- Frequency conversion speed regulation is adopted, with stable performance. The transmission system is equipped with overload automatic shutdown protection device, which is safe and reliable and reduces the pollution problem during filling and tamping.

- It is specially used for the production of various non-gas liquid filling and automatic rinsing of bottles before filling, nitrogen pre-filling in bottles and stoppering after filling.

- The design finishing speed meets the production of the machine, and the lid is not stuck stably.

| Size | Material | Bottle Height | Lid Diameter | Production Speed |

|---|---|---|---|---|

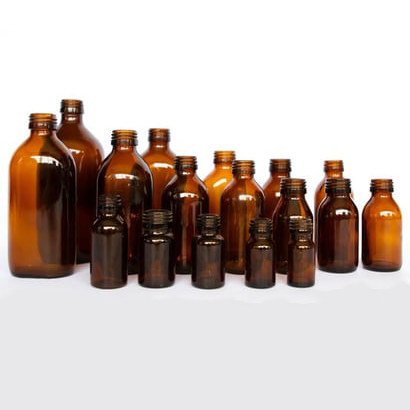

| 30 - 500ml | Glass Bottle HDPE |

80 - 280mm | ø25 - ø30 Aluminum joint plastic rotary cover |

200 bottle/min (The dose of 50ml shall prevail) |

-

LP-1 Bottle unscrambler system

- The designed bottle handling speed can meet the production of the host machine, stabilize the bottle handling, and smoothly do not pour the bottle

- The whole machine is made of stainless steel and aluminum profile, which is pollution-free and meets the requirements of food grade

- The operation speed of the bottle sorting machine adopts variable frequency control speed regulation, which is easy to operate

-

Spray sterilization and cooling system

- Design speed Satisfy production table operation, sterilization, and cooling to satisfy customer's request

- The equipment adopts trapezoidal temperature control mode for sterilization, cooling and flushing, so the temperature control, water pump start and stop and power control are controlled by PLC

-

Air Knife Drying Systems

- The designed water storage speed meets the production of the host machine, the bottle type operates stably, and the water-free film can be supplied to the labeling machine

- There are about 40 self-adjusting nozzles on the fan, which can manually adjust the outlet position according to the parallel height to achieve the best drying effect

- This machine mainly uses high-speed wind to forcibly remove the water droplets and water film on the shield from different directions to achieve the labeling effect

- High stability provides stable and consistent air volume and air pressure to ensure that the product reaches the required dryness

- The system can provide stable and consistent air volume and pressure to ensure that the product reaches the required dryness